pu光油-PU哑油-PU清漆

PU varnish - Pu dull oil - PU varnish

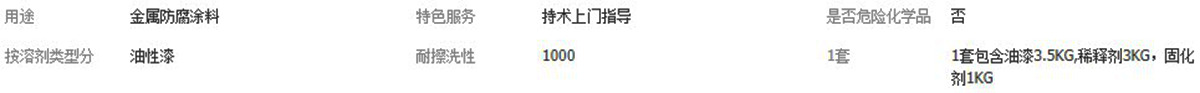

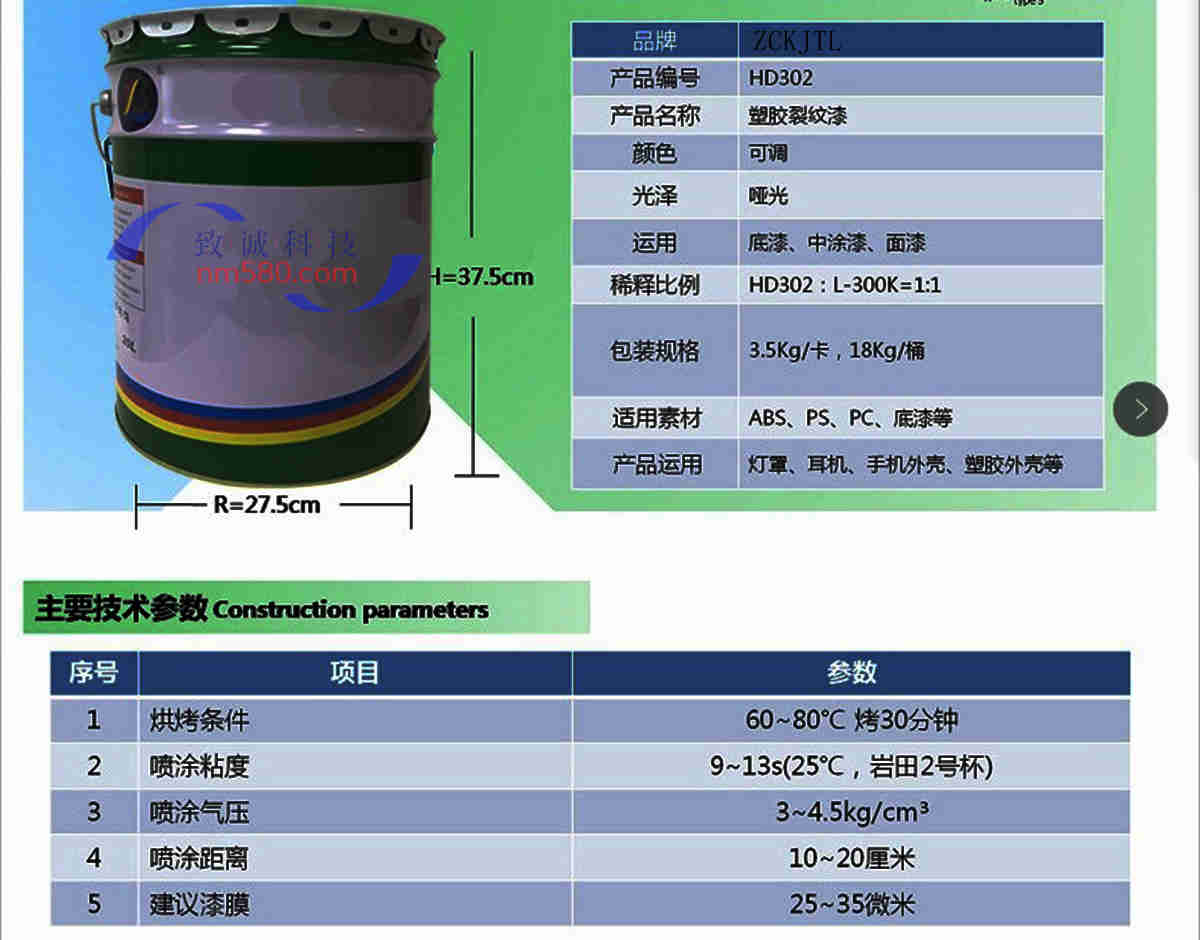

【理化参数】

[physical and chemical parameters]

【包装规格】

1套包含油漆3.5KG,稀释剂3KG,固化剂1KG

开油比例:(光油:固化剂:稀释剂)3:1:3;烤65-70度,30分钟

【主要组成】

由特殊羟基丙烯酸树脂、助剂、溶剂精制而成。以A、B两组分装。

【产品说明】

本品具有流平性好的施工性特点,制品表面,光泽高,丰满度好,硬度高,优异的附着力,抗污染和耐化学性。耐黄变性好,固含高,薄涂就可以得到很好的光泽。

【使用范围】

用于各种电动工具外壳、电脑外壳、电脑鼠标壳、手提式影音器材、CD机、照相机、电吹风外壳、运动器材、麦克风、剃须刀、手电筒外壳、电话、望远镜等塑料或金属制品、陶瓷、PLOY等工艺产品的底漆上的罩光。

[package specification]

One set contains 3.5kg paint, 3kg diluent and 1kg curing agent

Oil ratio: (varnish: curing agent: diluent) 3:1:3; Bake at 65-70 degrees for 30 minutes

[main components]

It is refined by special hydroxyl acrylic resin, auxiliary agent and solvent. They are packed in two groups A and B.

[product description]

This product has the construction characteristics of good leveling, high gloss, good fullness, high hardness, excellent adhesion, anti pollution and chemical resistance. Good yellowing resistance, high solid content, thin coating can get good luster.

[application scope]

It is used for covering the primer of plastic or metal products such as electric tool shell, computer shell, computer mouse shell, portable audio-visual equipment, CD player, camera, hair dryer shell, sports equipment, microphone, razor, flashlight shell, telephone, telescope, ceramics, ploy and other process products.

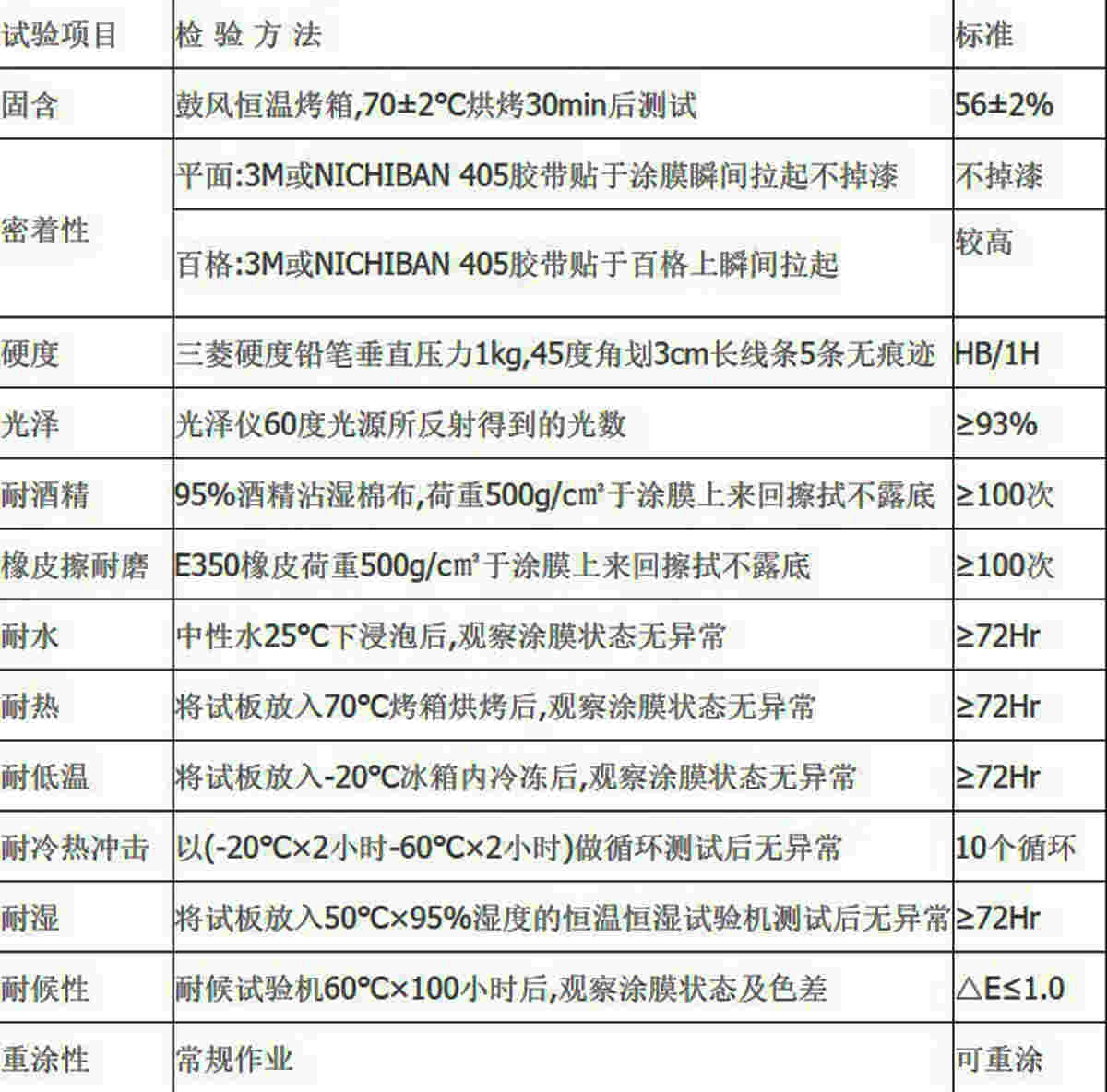

【施工工艺】

1.在喷涂前充分清洗底材,以确保优异的附着力和表面效果。

2.本品作业条件,温度: 15-30℃;湿度:(RH)≤75%

3.配套固化剂:PU-002 配套开油水:PU-605

4.开油比例: A组:B组:C组(油:固化剂:开油水)=3:1:3-4

5.喷涂粘度(岩田2号,25℃) : 8-11s

6.干燥条件: 65-70℃×30min(可自干)

7.喷涂空气压力: 4.5-6.5kg/c㎡

8.喷涂距离:10-20cm

9.喷枪口径:1.1-1.5mm

[construction technology]

1. Fully clean the substrate before spraying to ensure excellent adhesion and surface effect.

2. Operating conditions: 15-30 ℃; Humidity: (RH) ≤ 75%

3. Supporting curing agent: pu-002, supporting oil and water: pu-605

4. Oil ratio: group A: group B: Group C (oil: curing agent: oil) = 3:1:3-4

5. Spray viscosity (Yantian 2, 25 ℃): 8-11s

6. Drying condition: 65-70 ℃ × 30min (self drying)

7. Spraying air pressure: 4.5-6.5kg/cm2

8. Spraying distance: 10-20cm

9. Diameter of spray gun: 1.1-1.5mm

【施工注意事项】

1:湿度大于85%,或阴雨天施工请少量添加防白水。

2:被涂物表面油脂、灰尘、清除干净,水分烘干。

3:避免与不同系列产品混用,以免影响附着力及其它物性

4:油漆开稀后放置5分钟再喷涂

5:喷好后不可马上干燥,烘烤温度不可过高,以免烧焦底材

6:油漆调稀时用专用稀释剂以免影响漆膜外观及性能

7:开盖使用后务必盖紧,以免吸湿或风干

[construction precautions]

1: If the humidity is higher than 85%, or in rainy days, please add a small amount of anti white water.

2: The grease and dust on the surface of the coating shall be removed, and the moisture shall be dried.

3: Avoid mixing with different series of products, so as not to affect the adhesion and other physical properties

4: Leave the paint for 5 minutes before spraying

5: Do not dry immediately after spraying, and the baking temperature should not be too high to avoid scorching the substrate

6: When thinning the paint, use special thinner to avoid affecting the appearance and performance of the paint film

7: Be sure to cover tightly after use to avoid moisture absorption or air drying

包装规格:

5KG胶桶,20KG铁桶,配套稀释剂20KG蓝胶桶

Package specification:

5kg rubber barrel, 20kg iron barrel, 20kg blue rubber barrel with diluent

致诚科技根据产品特性匹配最佳的镀膜工艺方案,

致诚镀膜优势特点所在:专业、诚信、极致可靠。

Zhicheng Technology matches the best coating process scheme according to the product characteristics,

Zhicheng coating advantages: professional, honest, extremely reliable.

纳米喷镀 纳米喷镀材料 纳米喷镀设备 纳米喷镀加工 纳米喷镀厂家 纳米喷镀原料 纳米喷镀加工厂家 纳米喷镀配方 纳米喷镀技术 纳米喷镀工艺

纳米喷涂 纳米喷涂材料 纳米喷涂设备 纳米喷涂加工 纳米喷涂厂家 纳米喷涂原料 纳米喷涂加工厂家 纳米喷涂配方 纳米喷涂技术 纳米喷涂工艺

银镜喷镀 银镜喷镀材料 银镜喷镀设备 银镜喷镀加工 银镜喷镀厂家 银镜喷镀原料 银镜喷镀加工厂家 银镜喷镀配方 银镜喷镀技术 银镜喷镀工艺

银镜喷涂 银镜喷涂材料 银镜喷涂设备 银镜喷涂加工 银镜喷涂厂家 银镜喷涂原料 银镜喷涂加工厂家 银镜喷涂配方 银镜喷涂技术 银镜喷涂工艺

纳米电镀 纳米电镀材料 纳米电镀设备 纳米电镀加工 纳米电镀厂家 纳米电镀原料 纳米电镀加工厂家 纳米电镀配方 纳米电镀技术 纳米电镀工艺

环保电镀 环保电镀材料 环保电镀设备 环保电镀加工 环保电镀厂家 环保电镀原料 环保电镀加工厂家 小型电镀设备 环保电镀技术 环保电镀工艺