UV光油 - 蒸发电镀材料 - 塑胶UV清漆

UV light oil - evaporation plating material - plastic UV varnish

UV清漆 - 指甲油UV光油 - 美甲光油

UV varnish - Nail polish UV varnish - Nail Polish

【主要组成】

采用齐聚物、活性稀释剂、光引化剂为主要原料配制而成

【产品说明】

该产品喷涂或滚涂在基材表面之后,经过UV灯的照射,使其由液态转化为固态,进而达到表面硬化,其耐刮耐划的作用,且表面看起来光亮,美观、质感圆润。

【使用范围】

TPU软胶、PVC软胶、PEVA软胶、ABS美甲贴、PP料美甲贴、亚克力等产品喷涂

UV varnish

[main components]

It is made of oligomer, active diluent and photoinitiator

[product description]

After the product is sprayed or rolled on the surface of the substrate, it is irradiated by UV lamp to make it from liquid to solid, so as to achieve surface hardening. It is scratch resistant and scratch resistant, and the surface looks bright, beautiful and smooth.

[application scope]

TPU soft glue, PVC soft glue, PEVA soft glue, ABS nail stick, PP nail stick, acrylic and other products spraying

【理化参数】

[physical and chemical parameters]

【施工工艺】

1.在喷涂前充分清洗底材,以确保优异的附着力和表面效果。

2.本品作业条件,温度: 15-30℃; 湿度:(RH)≤75%

3.喷涂方式:直接喷涂,喷涂粘度(岩田2号,25℃) : 8 s ~9s

4.干燥条件: 300-400能量

5.喷涂空气压力: 4.5-6.5kg/c㎡

6.喷涂距离:10-20cm

7.喷枪口径:1.1-1.5mm

[construction technology]

1. Fully clean the substrate before spraying to ensure excellent adhesion and surface effect.

2. Operating conditions: 15-30 ℃; Humidity: (RH) ≤ 75%

3. Spraying method: direct spraying, spraying viscosity (Yantian 2, 25 ℃): 8 s ~ 9 s

4. Drying condition: 300-400 energy

5. Spraying air pressure: 4.5-6.5kg/cm2

6. Spraying distance: 10-20cm

7. Diameter of spray gun: 1.1-1.5mm

【施工注意事项】

1:被涂物表面杂物、油污必须清除。

2:施工调薄时请用专用稀释剂,以免影响漆膜外观、性能

3:油漆调制后,在使用前一定要静置10-15分钟后方可使用

4:涂装成品在常温下静置20-30分钟后,烘烤70oC*1H效果佳

5:开盖使用后务必盖紧,以免吸湿和风干;已加硬化剂之混合漆,不可入原桶,以免硬化

6:严格控制溶剂含水气,禁止用含醇类溶剂

7:遇反常气候涂装时,请洽敝司技术员,以寻求适当的涂装方法

8:油漆开稀后用300目过滤网过滤

[construction precautions]

1: Debris and oil on the surface of the coating must be removed.

2: Please use special diluent when thinning, so as not to affect the appearance and performance of paint film

3: After the paint is prepared, it must be allowed to stand for 10-15 minutes before use

4: After standing at room temperature for 20-30 minutes, the effect of baking at 70oC * 1H is good

5: Be sure to cover tightly after use to avoid moisture absorption and air drying; The mixed paint with hardener should not be put into the original barrel to avoid hardening

6: Strictly control the water containing gas in the solvent and prohibit the use of alcohol containing solvents

7: In case of abnormal weather coating, please contact our technician to find the appropriate coating method

8: The paint is thinned and filtered with 300 mesh filter

【包装规格】

色漆20KG,铁桶4L、25L花蓝桶

[package specification]

Paint20kg,Iron bucket 4L, 25L flower blue bucket

【用途范围及属性】

主要用于假指甲产品,可以上金葱粉然后喷UV光油,产品柔韧性好!耐弯曲性好!

[application scope and properties]

Mainly used for false nail products, can be golden onion powder and then spray UV varnish, product flexibility is good! Good bending resistance!

致诚科技根据产品特性匹配最佳的镀膜工艺方案,

致诚镀膜优势特点所在:专业、诚信、极致可靠。

Zhicheng Technology matches the best coating process scheme according to the product characteristics,

Zhicheng coating advantages: professional, honest, extremely reliable.

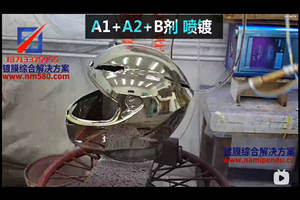

纳米喷镀 纳米喷镀材料 纳米喷镀设备 纳米喷镀加工 纳米喷镀厂家 纳米喷镀原料 纳米喷镀加工厂家 纳米喷镀配方 纳米喷镀技术 纳米喷镀工艺

纳米喷涂 纳米喷涂材料 纳米喷涂设备 纳米喷涂加工 纳米喷涂厂家 纳米喷涂原料 纳米喷涂加工厂家 纳米喷涂配方 纳米喷涂技术 纳米喷涂工艺

银镜喷镀 银镜喷镀材料 银镜喷镀设备 银镜喷镀加工 银镜喷镀厂家 银镜喷镀原料 银镜喷镀加工厂家 银镜喷镀配方 银镜喷镀技术 银镜喷镀工艺

银镜喷涂 银镜喷涂材料 银镜喷涂设备 银镜喷涂加工 银镜喷涂厂家 银镜喷涂原料 银镜喷涂加工厂家 银镜喷涂配方 银镜喷涂技术 银镜喷涂工艺

纳米电镀 纳米电镀材料 纳米电镀设备 纳米电镀加工 纳米电镀厂家 纳米电镀原料 纳米电镀加工厂家 纳米电镀配方 纳米电镀技术 纳米电镀工艺

环保电镀 环保电镀材料 环保电镀设备 环保电镀加工 环保电镀厂家 环保电镀原料 环保电镀加工厂家 小型电镀设备 环保电镀技术 环保电镀工艺